Technical page

Knock sensors

Typically located on the engine block, cylinder head or intake manifold. It is placed here because its function is to sense vibrations caused by engine knock or detonation by basically a sensitive microphone. The ECU uses this signal to alter the ignition timing and prevent detonation it senses. It will compare this information with its preset ECU tables to identify a valid knock condition (when listened a crackle or high 'splat' noise). If detected it will retard the ignition timing to protect the engine. I have had a few customers with this switched off!, of course from the factory the sensitivty and frequency sometimes isnt valid for a highly modified engines.

Diesel tuning

Seems a lot of people are applying petrol techniques to diesel whilst some elements are the same you cannot apply most of them, notably with the admission of VNT turbos. The turbo regulates boost and spool, in most cases decatting does nothing and you dont need bigger exhausts until running a lot more power and boost with the additon of bigger turbo's and more boost!. A common platform is the VW 1.9TDI i really think the limit on these is 2.1 bar especially with standard injectors, many have failed above this with other being ticking timebombs, often cracking pistons!.

Diesel tuning - Tuning boxes

Tuning boxes can be attractive option for diesels considering their ease of installation and ability to not effect warranty, however generally they cannot be compared to a full good remap. They are effectively a middle man not properly working with intertwined tables and often effect MPG (portraying they are more optimistic than they actually are). Most now on the market come with 2 sensors for boost and fueling and can be altered with a pot or dip switches. In most case they fall short of a true remap and are generally 25-50% less power and torque than a remap and torque spikes. We have seen these several times with expensive tuning boxes too!.

Benefits of Boost solenoids vs standalone boost controllers

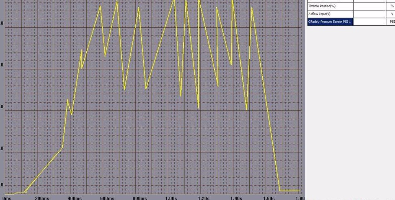

Traditional boost sensors work but dont provide feedback they are typically in the £150-300, a boost solenoid based on PID/PWM can perform the same function but can improve spool and remove osscilations due to talking to and from the ECU thus has the benefits of boost by gear and detecting over boost thus cutting fuel they are also typically in the £75 range!. However they typically have around 4 tables to adjust inc wastegate duty cydle, error and various others we can significantly effect boost and how its delivered and maintained.

Motorbike fuel filters inline with boost sensor

When using a external boost sensor or map sensor you can sometimes get harsh oscillations in boost or bad resonance, an inline motorbike fuel filter can act as an 'electronic dampner' and smooth out the signal. Some ECU's have a DSP chip for engine related sensor but not MAP/Boost sensors.

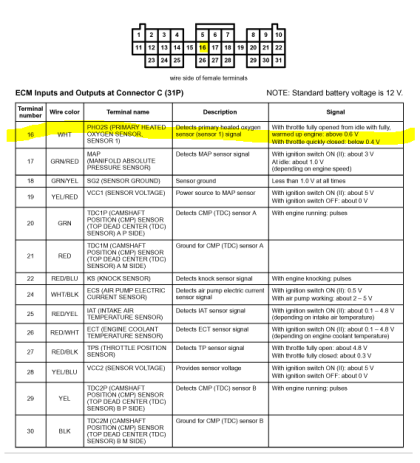

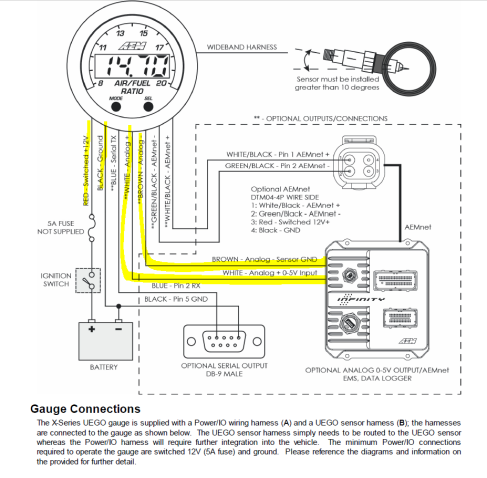

Wideband wiring and pinouts

This will be updated and expanded upon in the future but here are 2 common pinouts and wiring for widebands - generally most ECU's used on an S2000 will use C16 pin.

Files to download

Below are various manuals and software to download

Password is this website without .com and www

Honda S2000 (00-03) Service Manual.rar

Compressed file archive [27.2 MB]

e-manage PC Support Tool V1.49.zip

Compressed archive in ZIP format [5.5 MB]